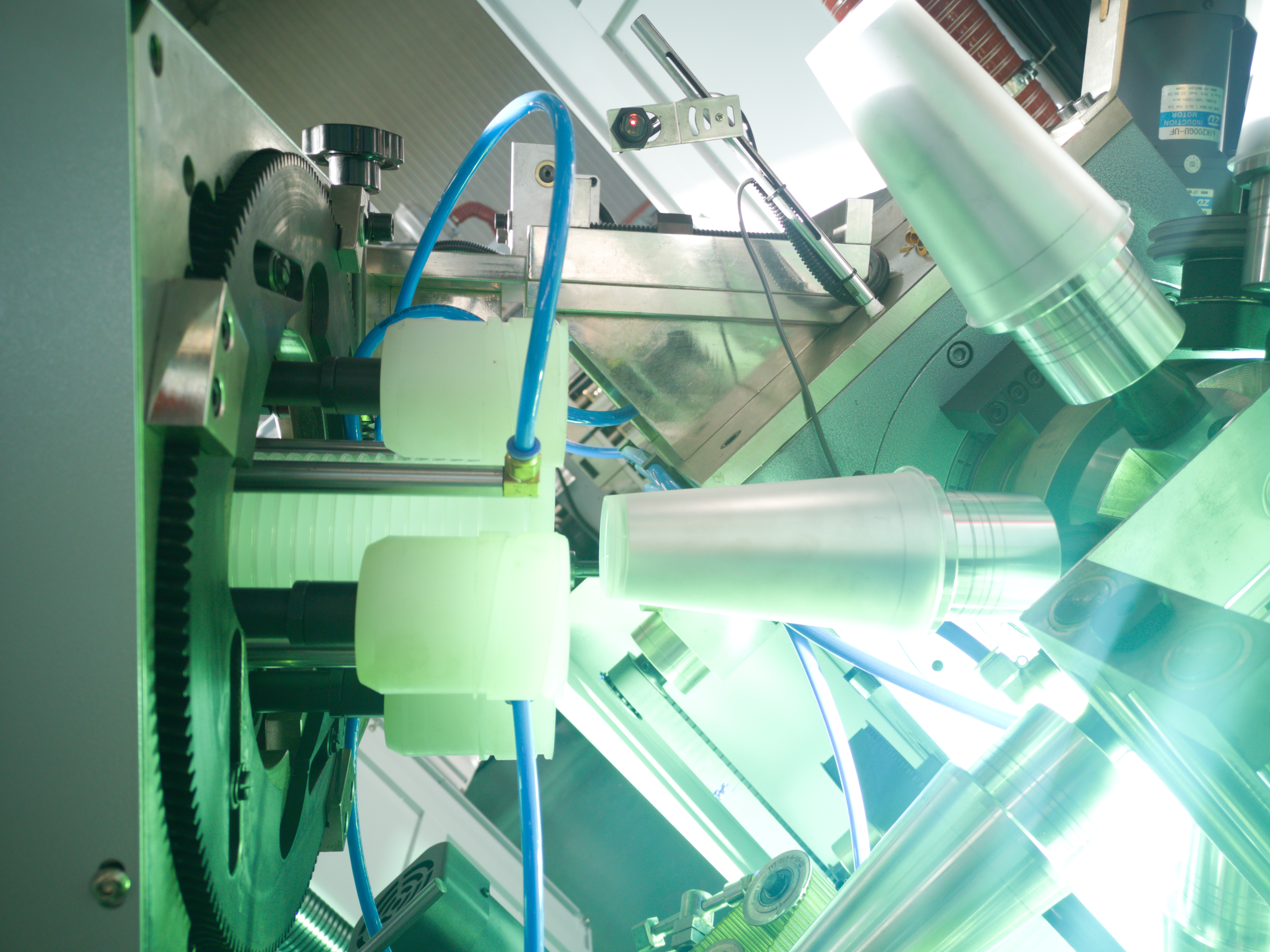

Source factory of curved printing machineDesign and manufacturing manufacturer for color printing and packaging

TEL:13872878482

0722-6699666

During the offset printing process, the occurrence of "ghosting" faults on continuously printed products is called "ghosting". In the actual production process, there are many factors that lead to the appearance of "ghosting".

1. Types of "ghosting"

In general, "ghosting" can be divided into mechanical "ghosting" and craft "ghosting". Mechanical ghosting is caused by mechanical action and is mainly influenced by factors such as printing pressure, ink rollers, and printing plates. The process of "ghosting" is caused by chemical changes in the ink during the printing process, and such "ghosting" is greatly affected by the production environment.

According to the positive and negative images of printed materials, "ghosting" can be divided into positive "ghosting" and negative "ghosting". The darker part of the printed product's pattern is called the positive image, and a lighter "shadow" is formed on its circumferential extension compared to the positive image, known as the "ghost shadow" of the positive image, as shown in Figure 1a; The lighter colored part of the printed product's pattern is called a negative image, which forms a darker "shadow" in the circumferential direction compared to the negative image, known as the negative image "ghost shadow".

2. Conditions for the formation of "ghosting"

Unreasonable layout design or improper adjustment of printing machines during the offset printing process are the main reasons for the appearance of "ghosting" in printed products, specifically:

① Patterns or text with high ink demand at the head of the printing plate;

② There are patterns with high ink demand and large area at the end of the printing plate;

③ The distance between the pattern and solid parts in the direction of the printing plate head and tail is exactly a multiple of the diameter of the ink roller.

Offset printing "ghosting" is an avoidable malfunction, and its focus is on prevention to avoid the occurrence of such malfunctions.

ISGO has an experienced team of professional designers who will design a suitable and personalized product image based on the differences in materials, structures, shape characteristics, and size requirements of the printed products, combined with the customer's brand culture. When changing the design and layout, they will design the layout reasonably. The appropriate layout arrangement can ensure that the grinding roller has enough ink time, so that the ink volume on the entire page is balanced, and technically minimize the occurrence of ghosting.

Of course, the following aspects can also be taken into account to avoid the occurrence of "ghosting":

(1) Adjust the ink supply corresponding to the "ghosting" area.

(2) Increase the flow rate of the ink roller. If the ink roller in the ink supply system cannot ensure the uniformity of the ink layer on the ink roller, it will also produce "ghosting". Therefore, increasing the amount of ink roller flow can be adopted to avoid the occurrence of "ghosting".

(3) Adjust pressure. To avoid such "ghosting", operators should adjust the pressure between each ink roller in the ink supply system to a better state.

(4) Check the tightness of the rubber blanket, the tightness of the printing plate, and whether the cylinder gears are worn.

Hotline

TEL:13872878482Tel